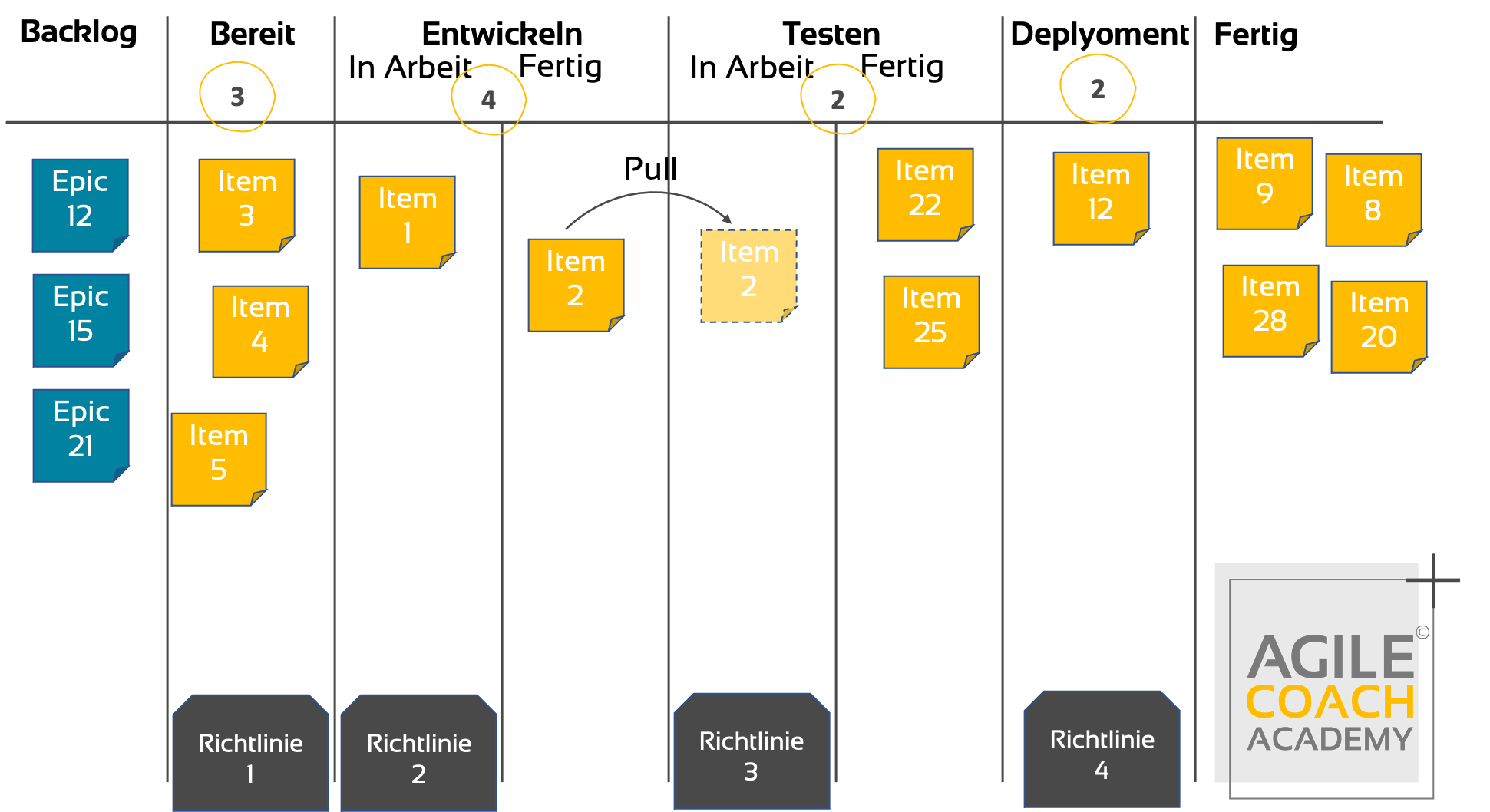

Kanban Model in Software Engineering

A kanban card is a visual representation of an item of work. It's an essential component of the kanban method, a work management framework that helps visualize work, limit work in progress (WIP), and maximize efficiency (or flow).

Kanban Calculation Kanban, Change management, Lean six sigma

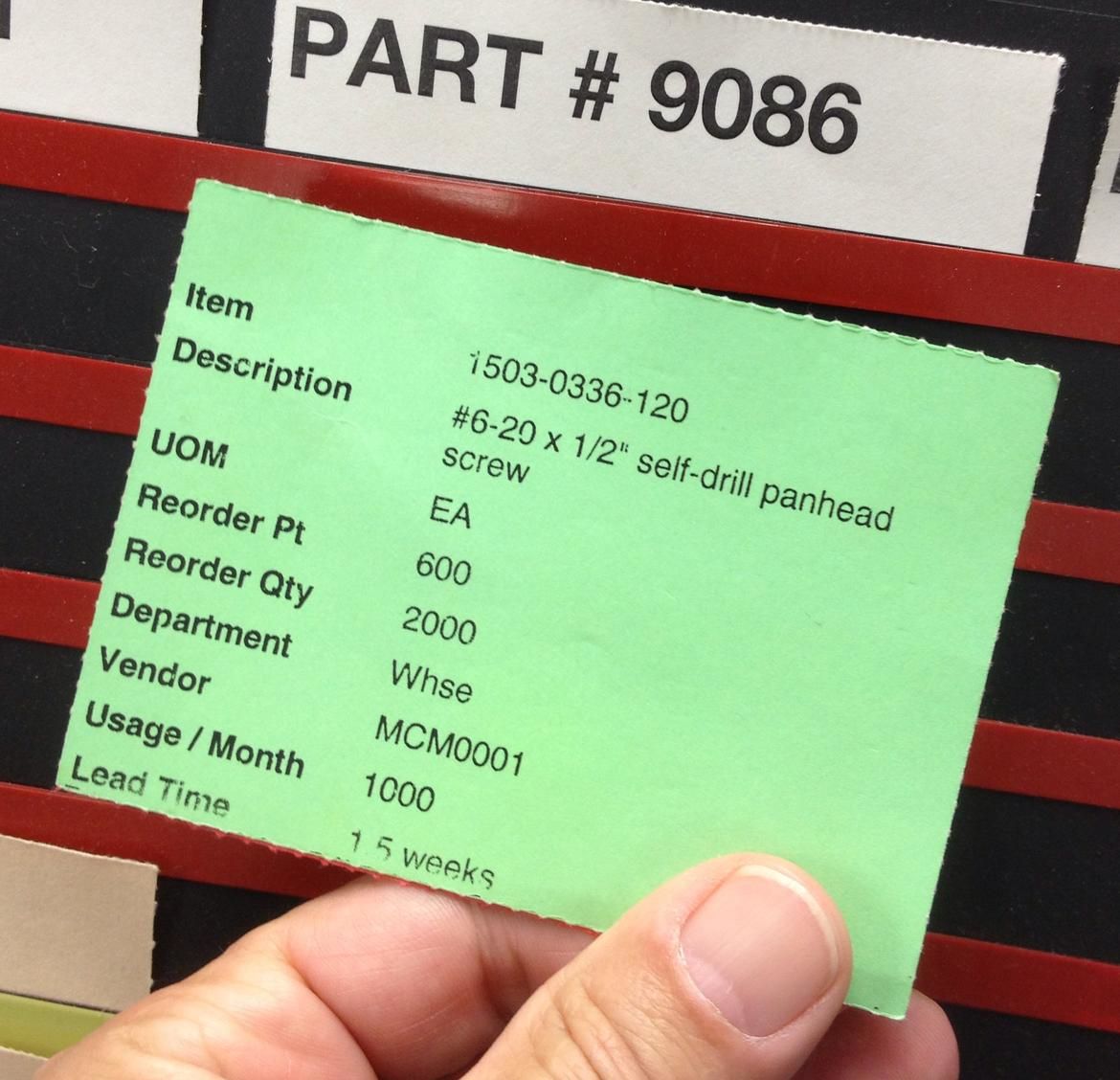

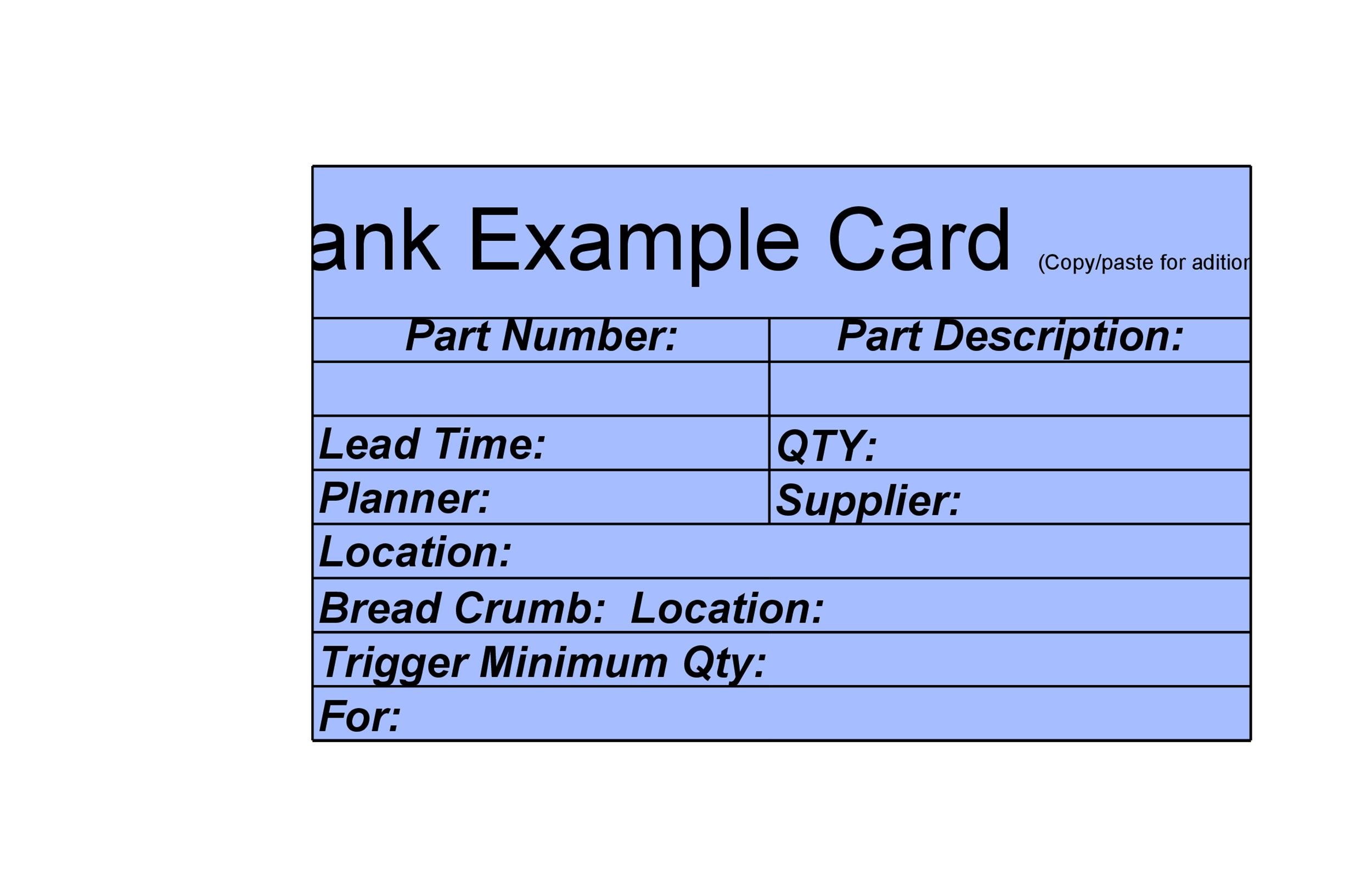

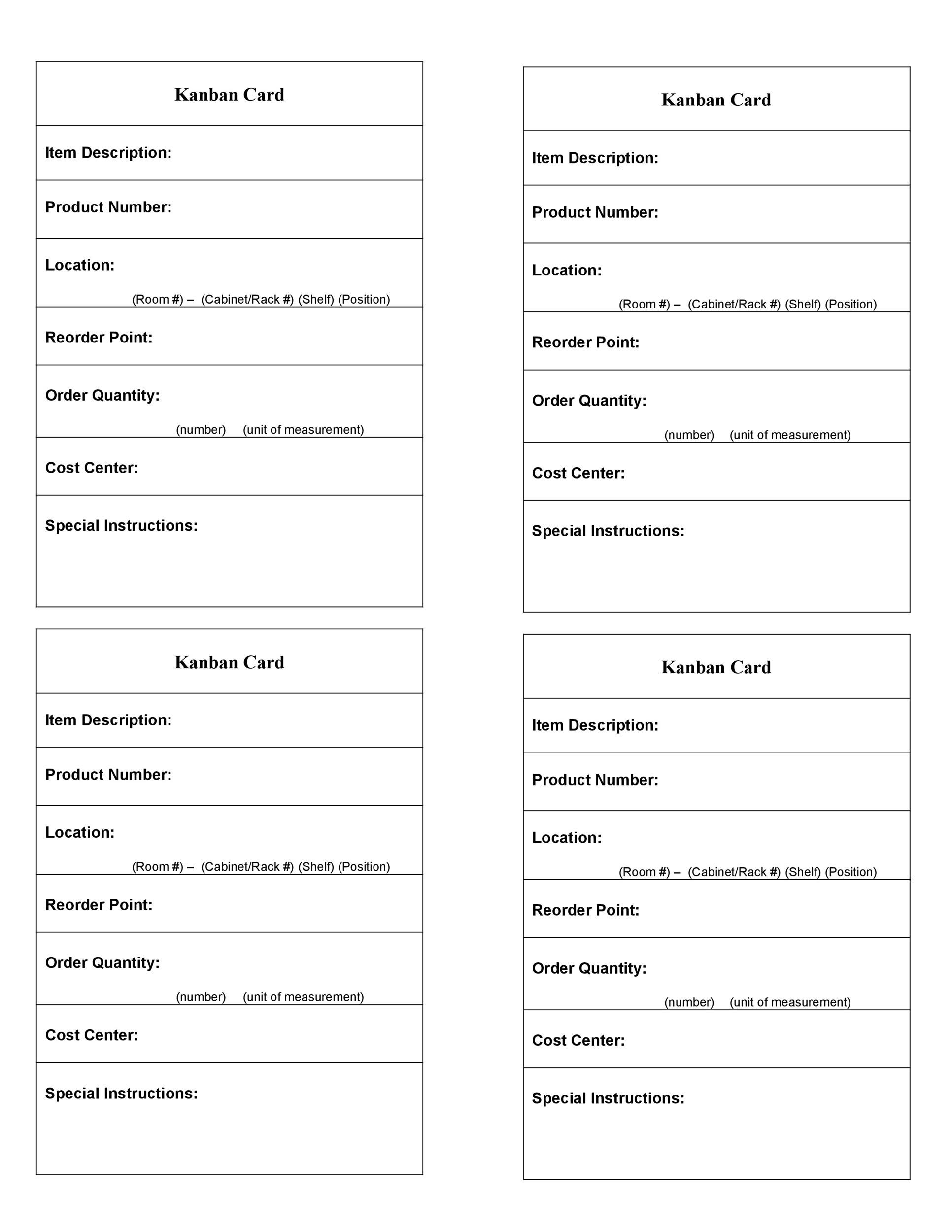

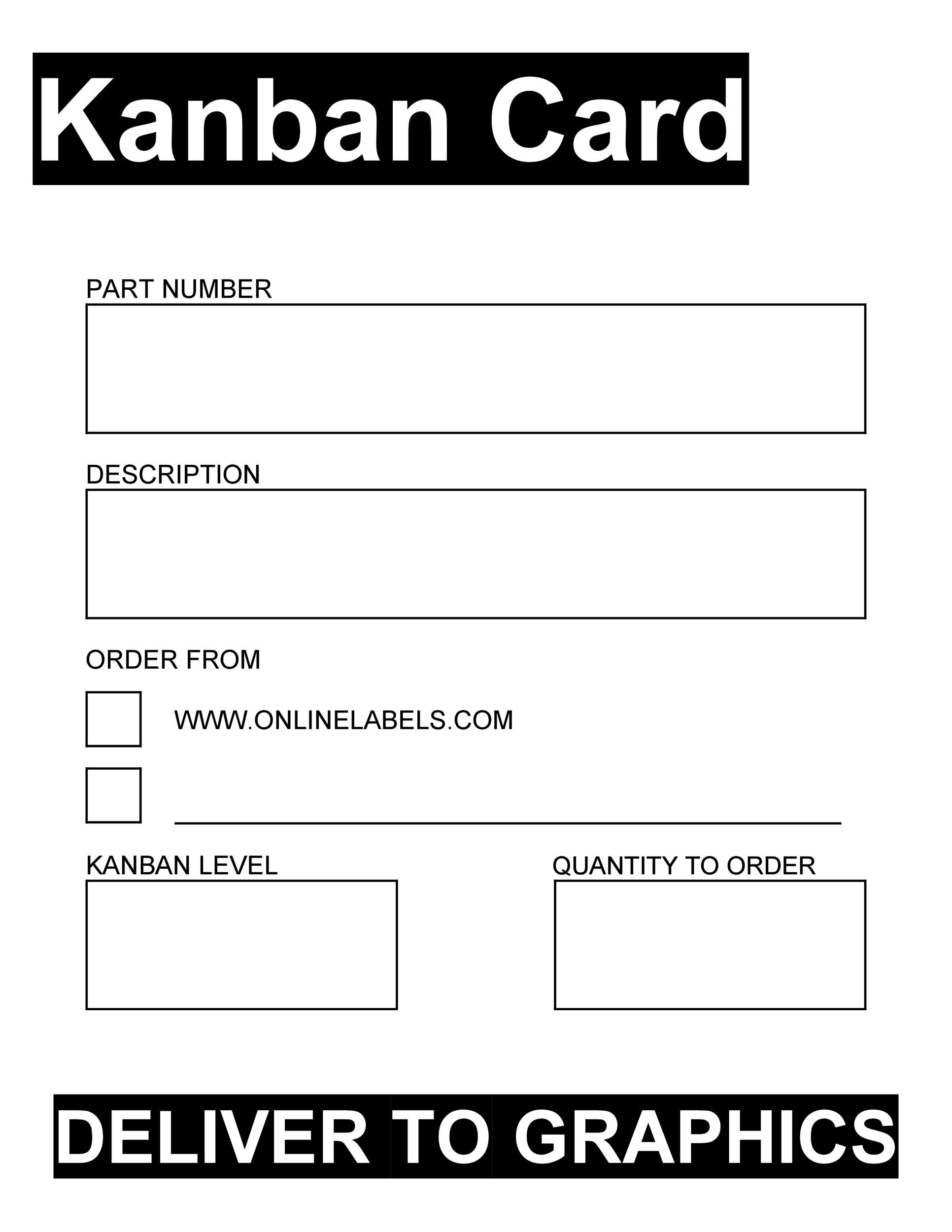

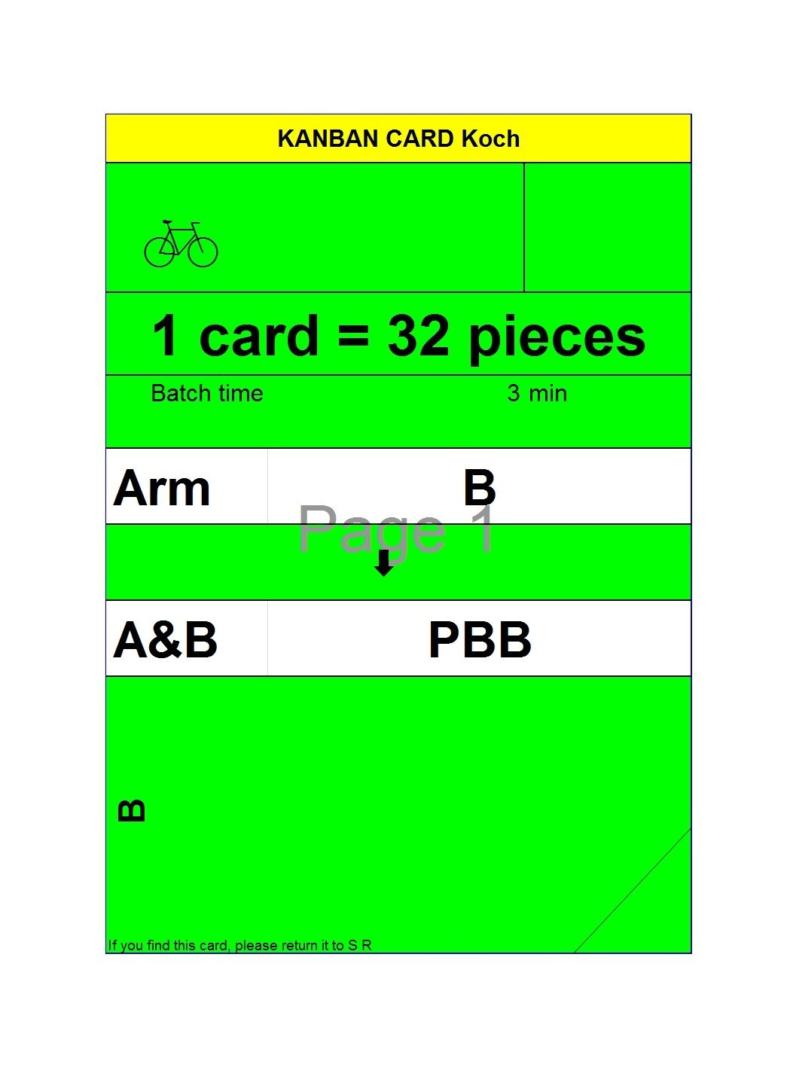

A Kanban is a low-tech, visual card that authorizes or request movement of material or process. It acts as a signaling system that notifies a supply partner that something is needed, and the amount needed. Below is an example of a Kanban: Notice that this Kanban is simple and very low-tech.

Benefits of Kanban Card Board Systems In the Workplace

Kanban cards are physical or digital cards that represent a unit of work or a batch of materials in a Kanban system. A Kanban system is a pull-based approach that limits the amount of.

Kanban System The Formula of Clarity Brain Soul & You

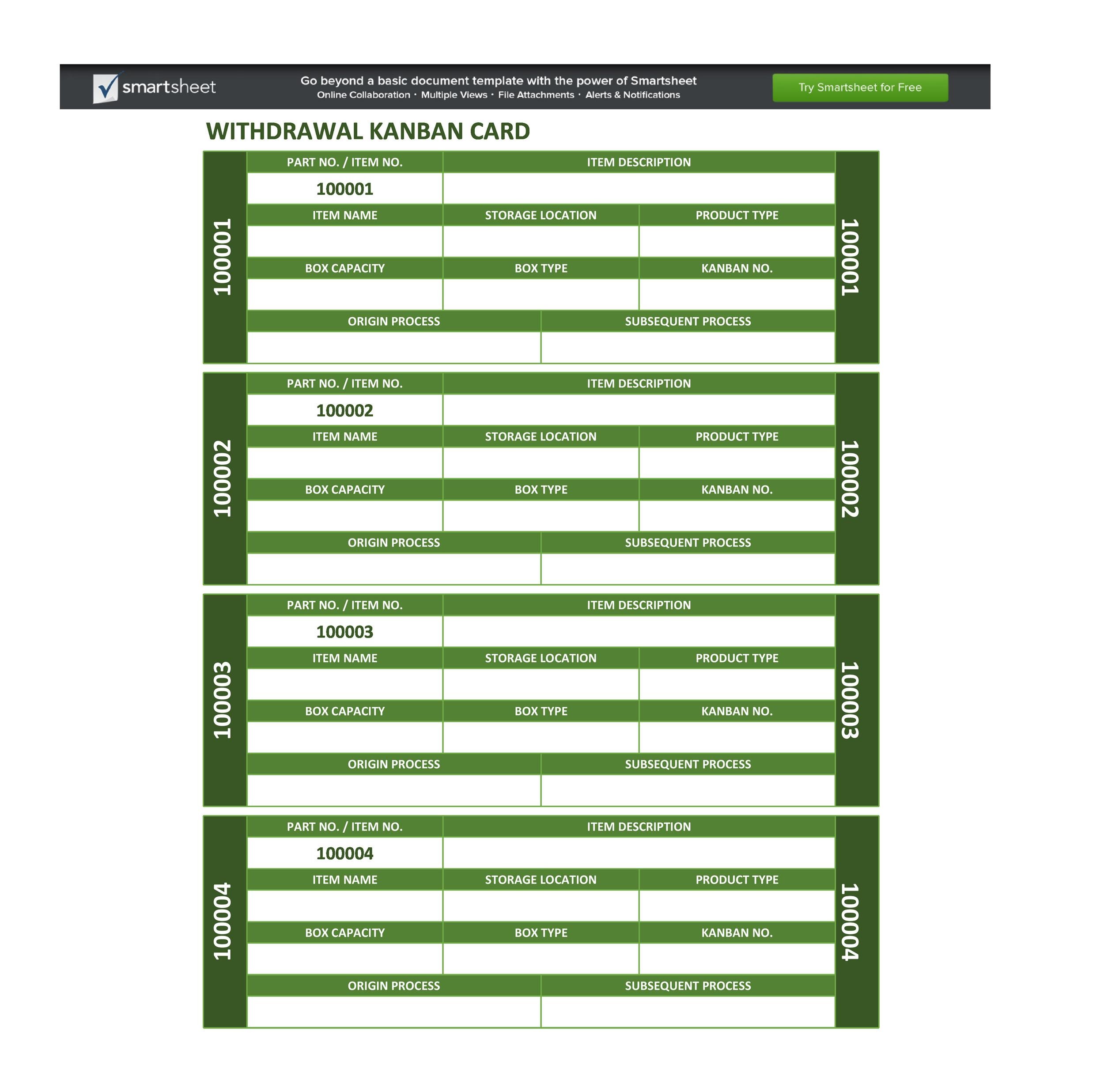

Simplified Kanban Formulas for Project Managers Try Smartsheet For Free By Kate Eby | August 8, 2016 Kanban simplifies project management, but one of the difficulties can be in finding a simple formula for the number of Kanban cards you should be using to increase efficiency and minimize waste.

25 Printable Kanban Card Templates (& How to use them) ᐅ TemplateLab

Kanban calculation using kanban formula, reorder point formula, and safety stock formula for your kanban inventory system. This kanban calculator takes into consideration important factors that most online kanban calculators don't.. If a kanban card (or empty container, or other signal) is not released to return to the kanban holder until.

Kanban Card Manage inventory by using a kanban system

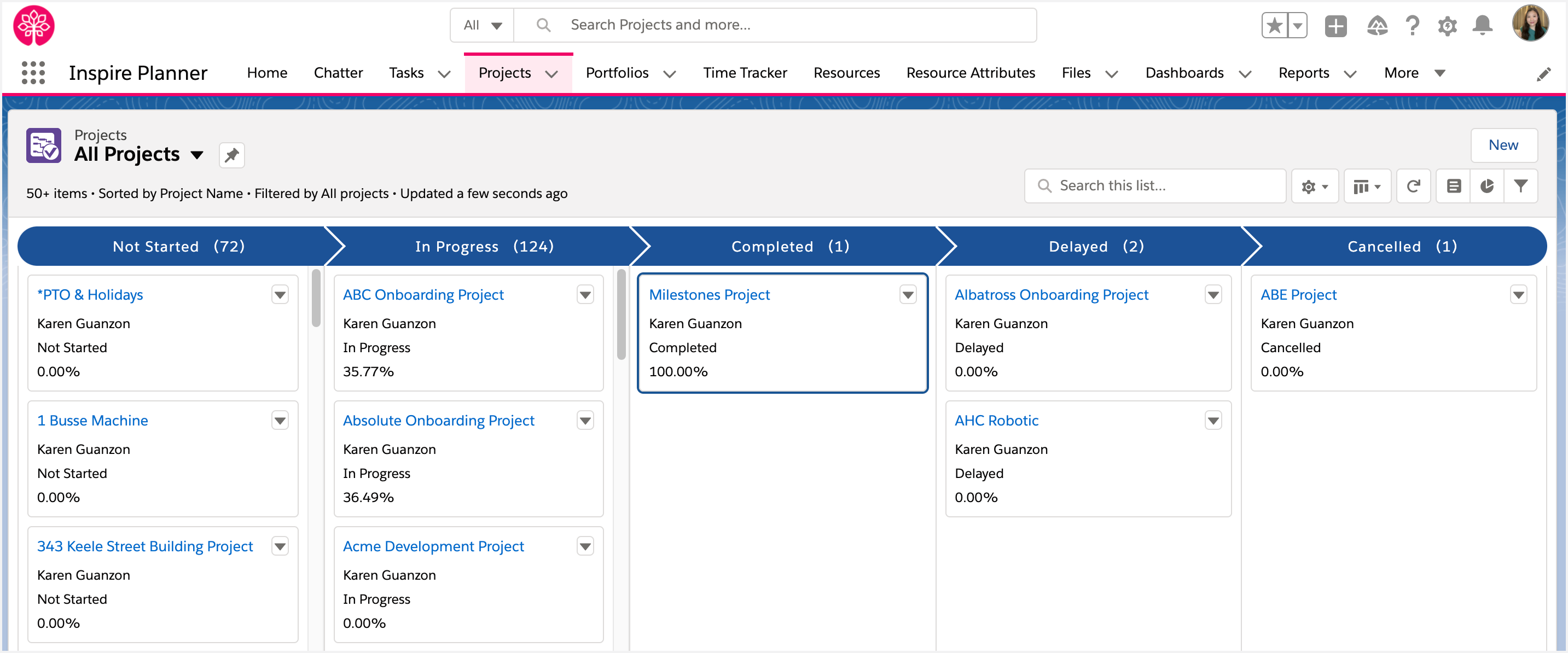

The Jira Software kanban board is designed to help teams continuously improve cycle time and increase efficiency. Kanban is enormously prominent among today's agile and DevOps software teams, but the kanban methodology of work dates back more than 50 years. In the late 1940s Toyota began optimizing its engineering processes based on the same.

Kanban Cards; Kanban System Types; Bins, Card, EBan, Faxban, CONWIP HubPages

The Kanban formula is a simple way to estimate the number of Kanban cards needed for a specific production stage or workstation. The formula is: Number of Kanban cards = (Daily demand.

Sample Kanban Board

Kanban[pronunciation?] (Japanese: カンバン Japanese pronunciation: [kambaɴ] and Chinese: 看板, meaning signboard or billboard) is a scheduling system for lean manufacturing (also called just-in-time manufacturing, abbreviated JIT). [2] Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. [3]

Standard Salesforce Kanban View for Projects Inspire Planner Help Center Inspire Planner

Kanban Calculation: The first step is to understand the formula for calculating the number of kanbans. This involves considering factors like customer demand rate and waiting time between replenishments. Demand Rate: Analyzing customer demand rate is essential in estimating how frequently items need to be replenished.

Pin On Kanban Videos Presentations Gambaran

Now, we can use the formula to determine the ideal number of Kanban cards for the factory. Kanban number = 100 *200 *(1+1)/ 15000 = 3 Remember, this number is an estimate.

25 Printable Kanban Card Templates (& How to use them) ᐅ TemplateLab

The ProjectManager kanban cards are highly dynamic. For example, you can add a to-do list to the card assigned to you and manage your own workflow. Each card can be tagged and prioritized to make it easy to sort. Plus, project managers can attach as many relevant documents and images as necessary to the card.

Kanban Cards YouTube

1. No. of kanban = (DD*LT+SS*SQRT (LT/TB))/KB+ (DD*EPEI)/KB Where: DD = Daily demand (units) LT = Replenishment leadtime (days) SS = Statistically calculated safety stock (units) SQRT = Square root TB = Time bucket of the safety stock data points (days) KB = Quantity per kanban (units)

25 Printable Kanban Card Templates (& How to use them) ᐅ TemplateLab

Here's the formula: N = DT (1+X)/C. Each letter stands for the following: N is the number of kanban cards needed before you replenish inventory. D is the demand for the part (i.e., how many are used within the lead time, sometimes measured in parts per day). T is the lead time, the length of production from beginning to end.

25 Printable Kanban Card Templates (& How to use them) ᐅ TemplateLab

There are two possible approaches. First, you can calculate the number of kanbans using a kanban formula (due to its length, split into a first post and this second post). Alternatively, you can estimate the number of kanbans and adjust the system as it is running (as shown in a third post ). Kanban Calculation - Part 2

Kanban Values, Impacts and HeuristicsAvailAgility AvailAgility

Kanban Explained - Calculation Formula and Example LeanVlog 40.1K subscribers Subscribe Subscribed 120 12K views 3 years ago Kanban System How to calculate the right number of Kanban? Here.

25 Printable Kanban Card Templates (& How to use them) ᐅ TemplateLab

Kanban is a Japanese term: 'kan' means 'visual' and 'ban' means card, so roughly translated, it means 'card you can see.' Taiichi Ohno, father of the Toyota Production System (TPS), originated the term and the Kanban card system in the 1950s to manage the flow of parts in just-in-time (JIT) production lines.